Brake pads are one of the most critical components in a vehicle's braking system. Their material composition directly influences braking performance, longevity, noise levels, and heat dissipation. Among the most common types available today are ceramic and semi-metallic brake pads. Understanding their differences can help drivers make the best choice for safety, performance, and value.

1. Overview of Brake Pad Materials

Ceramic brake pads are made primarily of ceramic fibers (similar to pottery), nonferrous filler materials, bonding agents, and small amounts of metal (usually copper). They were first developed in the 1980s to offer quieter, cleaner, and longer-lasting braking.

Semi-metallic pads are composed of 30–70% metals such as iron, steel, copper, or graphite, mixed with friction modifiers and filler materials bonded with resin. They have been the standard choice for many performance and heavy-duty applications.

2. Performance Comparison

Braking Power

Semi-Metallic: Generally provide superior initial bite and braking power, especially at lower temperatures. Ideal for performance and heavy-duty vehicles.

Ceramic: Offer smooth, consistent braking, but may lack the aggressive stopping power of semi-metallics, especially when cold.

Heat Dissipation

Semi-Metallic: Excellent heat dissipation, making them resistant to brake fade in high-performance or downhill driving.

Ceramic: Handle heat well under normal driving but can retain more heat under aggressive use, potentially affecting adjacent components like rotors.

Noise Levels

Semi-Metallic: More likely to produce noise and vibration due to their hard and abrasive nature.

Ceramic: Engineered for quiet operation and minimal vibration. Ideal for luxury or daily commuter vehicles.

Dust Production

Semi-Metallic: Generate more brake dust, which is darker and more likely to adhere to wheels.

Ceramic: Produce lighter-colored dust that is less visible and less corrosive.

3. Durability and Lifespan

Wear Rate

Semi-Metallic: Tend to wear rotors faster due to their abrasiveness, but the pads themselves can last long under certain conditions.

Ceramic: Longer pad life and gentler on rotors, leading to lower maintenance costs over time.

Temperature Tolerance

Semi-Metallic: Better suited for high-temperature conditions. Maintain performance even when hot.

Ceramic: Suitable for moderate temperatures. In extremely high-performance situations, they may underperform or glaze.

4. Cost and Value

Initial Cost

Semi-Metallic: Generally more affordable than ceramic pads, which is appealing for budget-conscious drivers or fleet owners.

Ceramic: Tend to be more expensive, but may offer better long-term value due to longevity and rotor friendliness.

Maintenance Costs

Semi-Metallic: Potentially higher due to increased rotor wear and dust cleanup.

Ceramic: Lower maintenance needs in normal conditions.

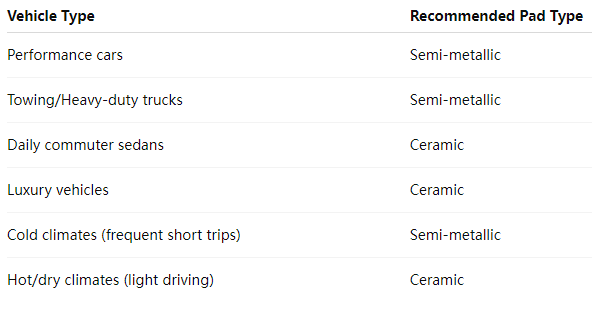

5. Application Suitability

6. Environmental Impact

Semi-Metallic: May include materials like copper and steel that are harder to recycle or contribute to environmental pollution.

Ceramic: Often promoted as eco-friendlier, with less reliance on heavy metals and lower dust emission.

7. Pros and Cons Summary

Ceramic Brake Pads

Pros:

Quiet operation

Low dust output

Long pad life

Gentle on rotors

Cons:

Higher cost

Less effective under high-stress driving

Lower performance in extreme cold or aggressive driving

Semi-Metallic Brake Pads

Pros:

Superior braking performance

Excellent heat dissipation

Better suited for performance or heavy-duty applications

Often more affordable

Cons:

Noisier

More brake dust

Faster rotor wear

8. How to Choose the Right Brake Pad

To choose between ceramic and semi-metallic brake pads, consider the following factors:

Driving Style

Aggressive or performance driving: Go with semi-metallic.

Smooth, city commuting: Ceramic is more suitable.

Vehicle Type

Heavy trucks, SUVs, or performance cars: Semi-metallic pads for strength and durability.

Light vehicles and hybrids: Ceramic pads for noise reduction and longevity.

Environment

Cold weather, mountainous terrain: Semi-metallic for better cold performance and heat handling.

Warm climates, flat terrain: Ceramic pads can last longer and run cleaner.

9. Final Thoughts

There’s no one-size-fits-all answer when it comes to brake pads. The ideal choice depends on your vehicle, driving conditions, performance needs, and budget. If you prioritize quiet, clean, and low-maintenance operation, ceramic brake pads are the better option. If you need raw stopping power, better heat management, and drive a heavier or high-performance vehicle, semi-metallic pads are a better fit.

General Recommendation:

For most everyday drivers, ceramic brake pads strike a better balance between performance, longevity, and comfort.

For enthusiasts or work vehicles, semi-metallic offers the durability and performance needed under load and heat.